OPGW is a specialized type of communication optical cable designed specifically for power transmission systems.

It integrates the functionalities of both an ordinary grounding wire and a communication cable within a single structure.

OPGW consists of a combination of optical fibers and metallic wires, often with a metallic protection layer made of high-strength materials such as aluminum-coated steel for the main force-bearing part, and lower-intensity materials like aluminum alloy or pure aluminum for the short-circuit current transmission part.

OPGW Fiber Optical Cable

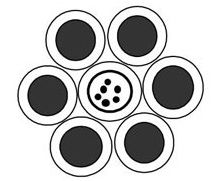

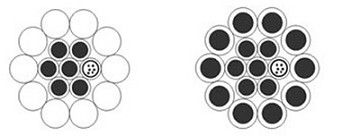

SUS central tube Layer strand Layer strand

Model:OPGW cable

Name:Optical Fiber Composite Overhead Ground Wire

Application:

☆ OPGW cable is mainly used in 500KV, 220KV and 110KV lines, limited by power cut, security and other elements, mostly used in new lines. Its applications are: high voltage over 110kv, with a longer span (usually over 250M);

☆ Easy to maintain, easy for line span, its mechanical property can meet a big line span;

☆ Outer OPGW is metal armoring, with no influence for high pressure electro-corrosion and degradation;

☆ To construct OPGW must cut power, resulting in greater loss, thus OPGW must be used in constructing high voltage line over 110kv;

☆ For OPGW performance index, the more short circuit current, the more need a good conductor to be metal armor, and reduce tension strength, while,

If the tension strength is certain, to increase short circuit current capacity, the only way is to enlarge metal section area, resulting in an increased cable Diameter and weight, so that security is a question for line pole strength.

Characteristics:

☆ Bio-function of ground wire and communication cable, avoid a huge expenditure to re-erect and re-maintain;

☆ Erect on top of power overhead line pole, need not to consider its best hanging point, electro-corrosion, and others.

☆ In the process of old line transformation, cable’s outer diameter and tension may be matched better than another ground wire;

☆ Big transmission capacity, good and reliable communication; excellent mechanical and electrical property;

Good security, long lifetime, and invulnerable to gun fire.

Technical Parameters:

Central Optical Fiber SUS Tube Structure (Parts) | |||

Structure Drawing | Structure:central optical fiber SUS tube structure with single stranded layer | ||

Order Type Model | OPGW-36B1-48 [59;11] | OPGW-40B1-58 [71;16] | |

Max. fiber count | 36 | 40 | |

Tube size | φ3.2 mm | φ3.5mm | |

Cable diameter | φ9.6 mm | φ10.5 mm | |

Cross-section carry area | 48 mm2 | 58 mm2 | |

Cable weight | 338 kg/km | 400 kg/km | |

Rated Tensile Strength(RTS) | 59 kN | 71 kN | |

DC resistance at20℃ | 1.782 Ω/km | 1.490 Ω/km | |

Short current capacity (40~200℃) | 11 kA2·s | 16 kA2·s | |

Linear expansion coefficient | 13.0×10-6/℃ | 13.0×10-6/℃ | |

Young’s modulus | 162.0 kN/mm2 | 162.0 kN/mm2 | |

Structure Drawing | Structure:central optical fiber SUS tube structure with double stranded layers | ||

Order Type Model | OPGW-30B1-127 [77;137] | OPGW-40B1-163 [99;226] | |

Max. fiber count | 30 | 40 | |

Tube size | φ3.0 mm | φ3.4 mm | |

Cable diameter | φ15.0 mm | φ17.0 mm | |

Cross-section carry area | 127 mm2 | 163 mm2 | |

Cable weight | 529 kg/km | 673 kg/km | |

Rated Tensile Strength(RTS) | 77 kN | 99 kN | |

DC resistance at20℃ | 0.329 Ω/km | 0.255 Ω/km | |

Short current capacity (40~200℃) | 137 kA2·s | 226 kA2·s | |

Linear expansion coefficient | 17.5×10-6/℃ | 17.5×10-6/℃ | |

Young’s modulus | 97.3 kN/mm2 | 97.3 kN/mm2 | |